Marine XII project in Congo: Installation of anchor piles

Following the installation of the drilling template, the Marine XII project has reached a new milestone with the installation of three anchor piles at the base of the Keel. These foundations will play a crucial role in securing the mooring system and ensuring the stability of the floating FLNG unit. This operation, carried out meticulously, relies on specialised equipment and rigorous coordination.

This article explains the sequence of operations and the technical challenges to overcome.

Positioning of the barge

Before drilling operations can begin, the Jack-Up Barge (JUB) is positioned on site and raised above sea level using its legs resting on the seabed. This positioning is essential to ensure optimal conditions for the following drilling operations.

Installation of the casing, the drilling guide

The casing, a metal guide tube, is installed to ensure accurate drilling:

- Positioning of the casing using the crane, keeping it vertical.

- Gradually lowering the casing into the water until it touches the seabed.

- Insertion of the casing into the gripper, a holding clamp protruding from the jack-up

- Disconnecting the crane to prepare for the next step.

Driving the casing: secure fastening

The piling hammer is positioned above the casing to drive it gradually into the seabed. This step is essential to ensure a secure fastening before drilling operations begin.

Objective: To anchor the casing securely so that the drill string can be guided accurately.

Driving a drilling rig installation, drilling rig installed

Start of drilling operations: drilling through rocky ground

The drilling rig is positioned above the casing with the casing in place. The drill string is lowered to the seabed to begin operations.

Main challenges of offshore drilling:

🪨 Particularly hard ground, requiring robust drilling equipment.

📍 Millimetre precision to ensure perfect alignment of the anchor piles.

🔎 Constant monitoring using ROVS and divers to adjust operations in real time.

Installing the anchor piles: a durable fix

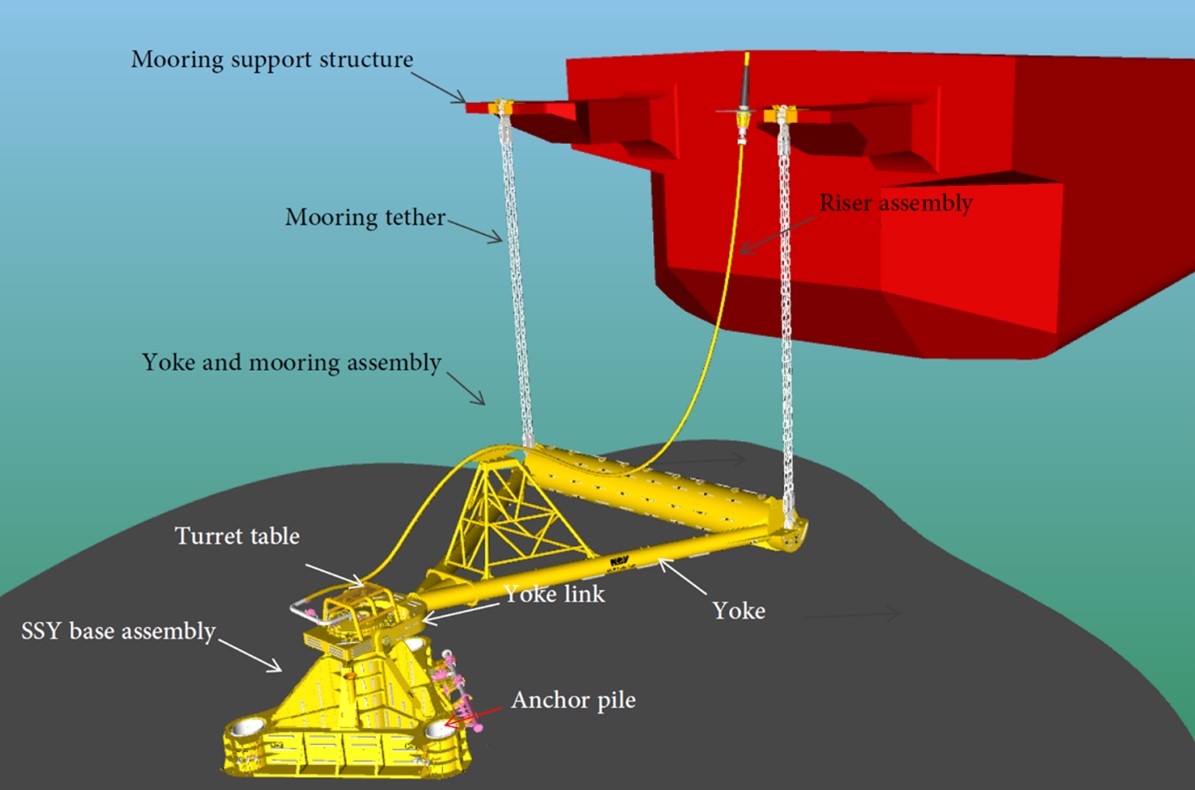

Once drilling is complete, the first anchor pile is inserted into the drilled hole and cemented. This operation is repeated twice more for the remaining piles. These form the foundations of the Yoke base, a key component of the FLNG mooring system.

With the three anchor piles in place, the foundations of the future mooring system are now ready. This installation represents a significant milestone for the Marine XII project, ensuring the safe offshore operation of liquefied natural gas (FLNG).

Our latest news:

Projects